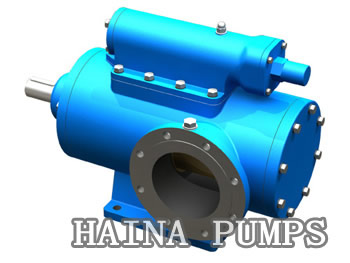

3G series three screw pump can be conveying lubricating oil, hydraulic oil viscosity is lower than 900 CST have certain lubricity liquid.Below to introduce 3G type 3 screw pump

3G screw pump including:3G for general 3Gc Marine type and special type.3G screw pump is a positive displacement pump rotor type, due to the driving screw and driven screw spiral groove on the pitch and they cooperate with bushing on the surface of the three hole, in the import and export of the pump number level formed between dynamic seal chamber, the dynamic seal chamber will continue to move from pump axial liquid pump discharge, and lose a liquid booster step by step, thus forming a continuous, smooth, axial movement of liquid pressure.

3G screw pump suitable medium range and performance:

3G three-screw pump of liquid for various not containing solid particles, non-corrosive oil lubricity and similar oil liquid, the liquid viscosity is 1.2 ~ 100 °E (3.0 ~ 760 CST), high viscosity liquid can be transmitted through heating after the viscosity.Flow range of 0.2~590 m3/h, high working pressure of 100 bar, high temperature 150 ℃.

3G series three screw pump structure:

3G series three screw pump structure:

1, simple structure, has the many kinds of structure forms, generally small flow of 0.2~6.5 m3/h, pump body and pump bushing (generally referred to as the pump body), is an organic whole to shaft seal for the mechanical seal.

Medium flow above the pump sleeve is fixed in a separate pump body, big flow made double suction pump more structure horizontal installation, depending on the medium of the shaft sealing has two kinds of mechanical seals and packing seal.

3G Marine pump installations have horizontal and vertical two kinds, prime mover for Marine ac or dc motor.

2, long service life: 3G three-screw pump active screw driven by a motor, there is no mechanical contact between master and slave rod, and by a liquid pressure driven from rod rotated on its axis, the Lord, from between rod, screw and bushing is a layer of oil film protection, thus pump mechanical friction small, life is a permanent.

3, of liquid in a 3G three-screw pump axial uniform motion in a straight line, so the pressure fluctuation is small, flow stability, low noise, because of the moving parts are inertia small, small starting torque and vibration.

4, 3G three screw pump with high suction ability.

5, in order to ensure the 3G three screw pump, motor and the safety of the pipeline system, secondary flow above the screw pump is with safety valve, when pressure exceeds the set pressure of the relief valve, high pressure oil will flow back to the inlet of the pump.

3g screw pump data sheet:

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mono Screw Pump G Series

Mono Screw Pump G Series Asphalt Screw Pump 3QGB Series

Asphalt Screw Pump 3QGB Series Stainless Steel Mono Screw Pumps

Stainless Steel Mono Screw Pumps